When your furnace stops heating, it can be due to a variety of issues. A faulty gas valve is one of the most common culprits. Other problems like power disruptions, incorrect thermostat settings, or clogged air filters may also cause your furnace to stop working. If you’ve ruled out these simple causes, it’s time to focus on the gas valve. A malfunctioning valve could be causing the gas supply to be interrupted, preventing the burner from firing properly.

In many cases, replacing the gas valve may require a professional technician. However, before scheduling a service call, you might be able to discover and resolve a related problem yourself, like checking for blockage or gas leaks. Identifying the root cause can restore your home’s heating system quickly, saving you both time and money.

What is a Furnace Gas Valve?

A furnace gas valve is a crucial component in a gas-powered heating system. It helps regulate the flow of gas from a supply line or propane storage tank. This valve opens and closes to allow or restrict gas flow to the pilot light and burners, ensuring the system works safely and efficiently.

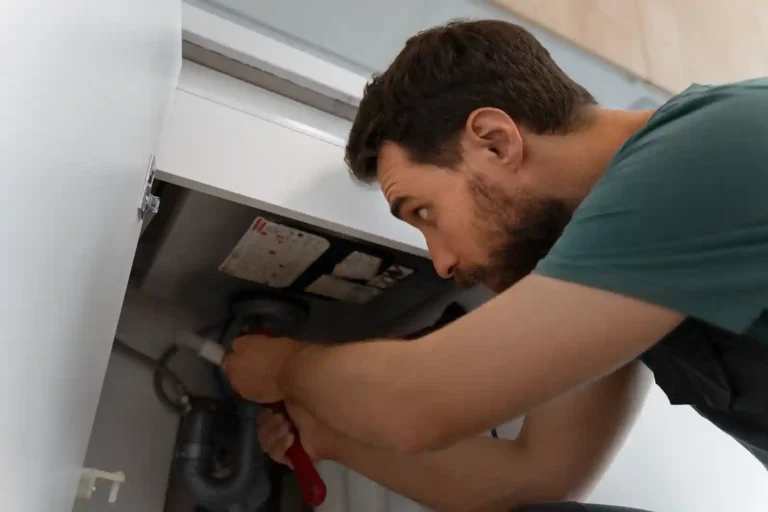

Where is the Furnace Gas Valve?

To find the furnace gas valve, start by locating the black metal gas pipe that enters the furnace cabinet. Once you’ve found it, follow the line until you see a small box with a switch or dial labeled “on” and “off.” This is the key component that controls the gas flow inside your furnace, usually found behind the access panel.

Furnace Gas Valve: How It Works

A furnace gas valve is essential for controlling gas flow and ensuring that your furnace operates safely. The gas valve opens and closes to regulate gas pressure and maintain temperature. It is made up of two internal, consecutive valves: the safety valve and the main valve. The safety valve is responsible for supplying gas to the pilot light, while the main valve controls the gas flow to the burners once the pilot is lit. This system is crucial to keep your furnace running smoothly and safely, as it helps prevent gas leaks and other hazards.

For the safety valve to work, a thermocouple is involved. The thermocouple sits in the pilot light’s flame and detects if the flame is burning correctly. If the flame goes out, the thermocouple’s metal tip cools, which signals the gas valve to shut off and stop the flow of gas. The thermocouple also produces current that energizes the gas valve’s solenoid. When the solenoid is activated, it powers an electromagnet that holds back a spring-loaded plunger. This plunger is what opens the safety valve and allows gas to flow.

When the pilot light is burning, the gas flow moves through the safety valve, travels through the manifold, and reaches the main valve. A 24-volt transformer controls the main valve, which is connected to a larger pipe than the safety valve. If the pilot light goes out or any issue arises, the system is designed to shut down to prevent gas leaks. The gas valve is also wired to other furnace safety devices that ensure the furnace operates safely at all times.

Types of Gas Valves

Combination valves and gas chain valves are two types of furnace gas valves.

Gas Chain Valve

A gas chain valve is made up of fuel system components that are separate but joined in a series. These valves have become obsolete because they are bulky, expensive, and prone to leaks. The system includes a manual valve with a handle to stop the flow of gas to the furnace. A gas regulator reduces gas line pressure and helps the manifold distribute gas to the burners, and it’s adjustable.

A solenoid valve is electrically operated and opens when the thermostat calls for heat. The pilot safety mechanism uses a current from the pilot flame, via a thermocouple and wire, to activate an electromagnet that controls the manual valve and ensures safe gas flow.

Combination Gas Valve

In the 1960s, the gas chain valve was replaced by the combination gas valve, which combined all the components into one packaged unit. While it served the same functions as the previous design, modern furnaces now rely on electronic controls to operate gas valves more efficiently. As a result, the combination valve has been phased out in favor of newer technologies, though it remains in use in older systems.

Furnace Gas Valve: Signs of a Faulty Gas Valve

When it comes to maintaining your furnace, a faulty gas valve can lead to serious issues, compromising not just the efficiency of your HVAC system, but also the safety of your home’s air. Gas valves are crucial in controlling the flow of gas to the furnace, and any malfunction could be a sign of a bigger issue. Below are some key indicators to watch out for, so you can spot a faulty valve early and take the necessary steps to resolve the situation.

1. Gas Leak or Natural Gas Odor

One of the most noticeable signs of a faulty valve is a gas leak. If you start to smell natural gas odor, which is often described as rotten eggs or sulfur, it’s a major red flag. Gas leaks can be toxic, flammable, and hazardous to both your health and the safety of your home. This gas leak could be coming from a valve that isn’t sealing properly, allowing gas to escape. The smell should never be ignored, as it could signal a dangerous situation that needs immediate attention.

2. Furnace Total Shutdown

If your furnace suddenly executes a total shutdown and refuses to turn on, it could be due to a malfunctioning gas valve. In this case, the gas valve might not be allowing enough gas to flow to the furnace, causing it to shut down as a safety precaution.

A furnace shutdown is often a direct result of the system not receiving the right amount of gas to operate efficiently. If this happens, it’s best to have the system inspected by a professional HVAC company to assess the situation.

3. Valve Becomes Flooded or Partially Submerged

In some cases, water damage can lead to the valve becoming flooded or partially submerged in flood water. If this occurs, it can cause a malfunction in the valve’s operation, making it difficult for the furnace to receive the correct amount of gas.

This is particularly concerning in areas where flooding is common, as water damage could affect the gas valve’s integrity, leading to gas leaks or even complete system failure.

4. Gas Valve is Damaged or Faulty

Sometimes, the valve itself may simply be worn out or defective. A faulty gas valve will not function properly, causing erratic flow or a complete disruption of gas to the furnace. A malfunctioning valve can lead to inconsistent heating, and in extreme cases, can stop the furnace from working entirely. If you suspect the gas valve is damaged, it’s crucial to have it replaced by a certified technician to prevent further complications.

5. The Gas Flow is Unable to Dissipate Properly

Another issue you might encounter is when the gas flow is unable to dissipate properly. This can occur if the valve fails to fully open or close, allowing gas to back up or get trapped in the system. This buildup can lead to dangerous pressure in the lines, which could cause a gas leak or even an explosion if not corrected. If the furnace is not heating properly, or if you notice any unusual sounds or smells, it’s best to call a professional to inspect the system immediately.

6. Difficulty Turning the Gas Supply On or Off

If you experience difficulty turning the gas valve on or off, it could be an indication of a serious problem. Gas valve issues can be caused by corrosion, debris, or a mechanical failure within the valve itself. A stuck valve could either prevent the furnace from receiving gas or cause gas to leak uncontrollably. This is a dangerous situation that requires urgent attention from a professional to avoid further damage to the system or a potential gas leak.

7. Potential Risks to Health and Safety

The biggest concern with a faulty valve is the potential risk to health and safety. If a gas leak occurs, it can lead to dangerous situations, such as the buildup of toxic, flammable, and hazardous gases in your home.

Over time, prolonged exposure to a gas leak can result in headaches, dizziness, and even more severe health problems. In some cases, a gas leak can lead to a catastrophic fire or explosion if the gas accumulates and ignites. Always take any indication of a gas leak seriously and consult a professional opinion as soon as possible.

Troubleshooting a Gas Regulator Valve

When your furnace doesn’t seem to be heating as it should, the issue could be related to the gas valve. The gas supply might be interrupted, or there could be an issue with the ignition source, making it difficult for the furnace to function properly. Here’s a guide to help you troubleshoot the gas valve and other related components to get your system up and running again.

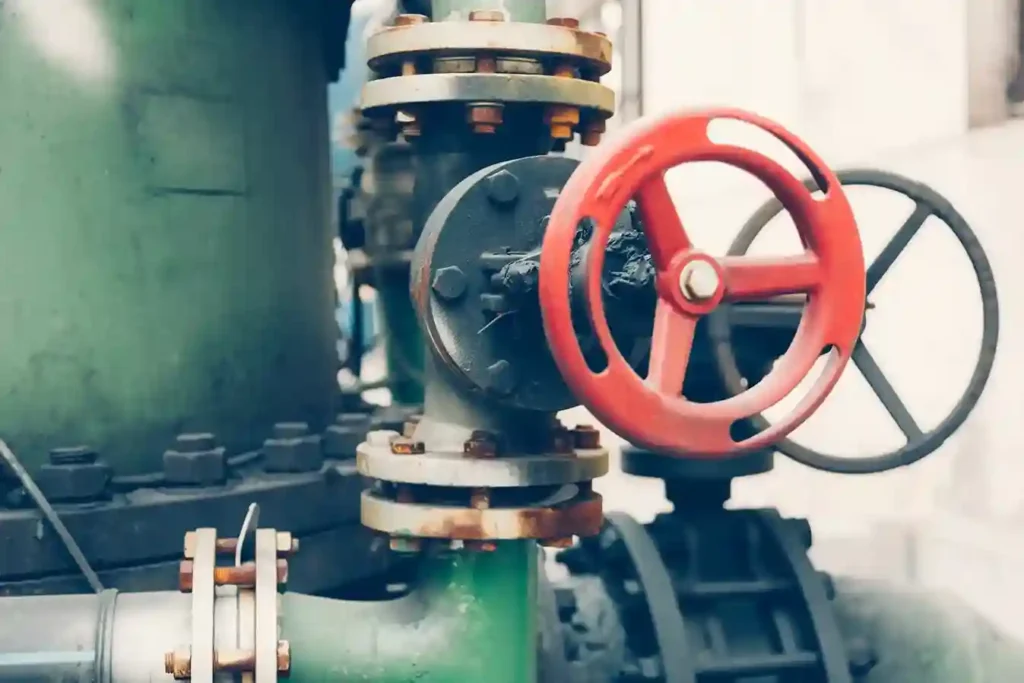

Check the Gas Supply and Valve Position

First, ensure that the main supply valve is fully open. If it’s in the off position, your furnace won’t receive any gas, and the system won’t operate. If you notice a black metal gas pipe leading to the furnace, check that the valve is positioned correctly.

- Brightly colored lever or knob: Make sure that the lever or knob on the gas valve is in the on position.

- Perpendicular valve: If the valve is perpendicular to the gas pipe, it’s most likely in the off position.

- Gas flow: You need to ensure the gas is flowing correctly for the furnace to ignite.

If everything looks fine with the gas valve, move on to the next part of troubleshooting.

Inspect the Ignition Source for Proper Function

The ignition source plays a vital role in lighting the furnace. It could either be a pilot light or an electronic ignition system, depending on the model. If there is a problem with the pilot light or the electronic ignition, it may prevent the burners from igniting properly.

- Pilot light: If your furnace uses a pilot light, check that it’s lit. If not, it may need to be relit or checked for issues such as gas flow interruption or dirt buildup.

- Electronic ignition: If you have an electronic ignition, make sure you see a blue flame or red glowing ignitor when the furnace tries to ignite. This means the ignition system is working properly.

- Burners: If there’s no ignition, the burners won’t fire up. Check for issues with the gas valve, pilot, or ignitor.

Examine Gas Valve Wires for Damage

If the gas valve is not responding, there may be issues with the electrical connections. This is where you need to check the gas valve wires.

- Damaged wires: Look for cracked, frayed, or scorched wires, as these can prevent proper function.

- Multimeter test: Use a multimeter to check for proper voltage at the terminals. Check both AC voltage and the furnace’s power to the control board.

- Check the terminals: Make sure the probes are connected securely and there is no corrosion or breakage in the wiring.

Inspect the Gas Valve Coil for Issues

If the furnace still isn’t working, the issue might be with the gas valve coil. The coil controls the gas flow, and if it’s malfunctioning, it will prevent the system from starting.

- Stuck closed valve: A bad coil can cause the gas valve to stay stuck in the closed position, preventing any gas from flowing to the furnace.

- Solenoid coil: Use a multimeter to check the resistance of the solenoid coil. If the reading shows “OL,” the coil is likely faulty.

- Voltage check: Check that the coil is receiving proper voltage from the control board.

Address Inconsistent Flame Issues

If you notice inconsistent flame from your furnace’s burners, the problem might be with the flame sensor or the burners themselves.

- Flame sensor: A dirty or faulty flame sensor can cause the furnace to shut down or not heat properly. If necessary, clean or replace the sensor to ensure proper functionality.

- Burners: The burners may need cleaning or servicing if they are producing an irregular flame. If the furnace’s flame is too weak or inconsistent, it may be due to a fuel supply issue or dirty components.

- Shut-off: The furnace may shut off automatically if the flame becomes inconsistent, indicating a safety concern.

Check for a Safety Trip Event

If your furnace has undergone a safety trip, it may shut down to prevent further damage. Safety devices are in place to protect the system from dangerous malfunctions.

- High limit switch: This safety feature prevents the furnace from overheating. If the temperature gets too high, the system will shut down to protect the heat exchanger.

- Blower motor speed: A malfunction in the blower motor speed can also trigger a safety shutdown. Check the settings in your owner’s manual to make sure the system is operating at the right speed.

- Reset: If everything looks normal after inspection, try resetting the system and follow the instructions in the owner’s manual to restart the furnace safely.

Inspect Ductwork for Blockages

Your furnace may be running into problems if there are issues with the ductwork. Blockages or damage in the ducts can affect airflow, causing the system to overheat or shut down.

- Crushed or cracked ducts: Inspect the ducts for any damage. A dirty air filter can also cause similar issues, restricting airflow and causing the furnace to overheat.

- Shut down prevention: If the airflow is blocked or reduced, your furnace may shut down to prevent overheating. Check the ducts for any visible obstructions.

- Overheating: An airflow problem can lead to the furnace overheating, which will activate the safety shut-off system. Replace any dirty air filters and check for cracks or blockages in the ducts.

Conclusions

Gas furnace valves play a critical role in ensuring the safe and efficient operation of heating systems. They regulate the flow of gas, preventing leaks and ensuring proper combustion. By providing control over the burner and ignition process, these valves help maintain consistent temperature levels and protect the furnace from potential damage.

Regular maintenance and timely replacement of faulty valves are essential for maximizing furnace lifespan and safety. Overall, well-functioning gas furnace valves contribute significantly to the reliability, performance, and safety of the heating system.